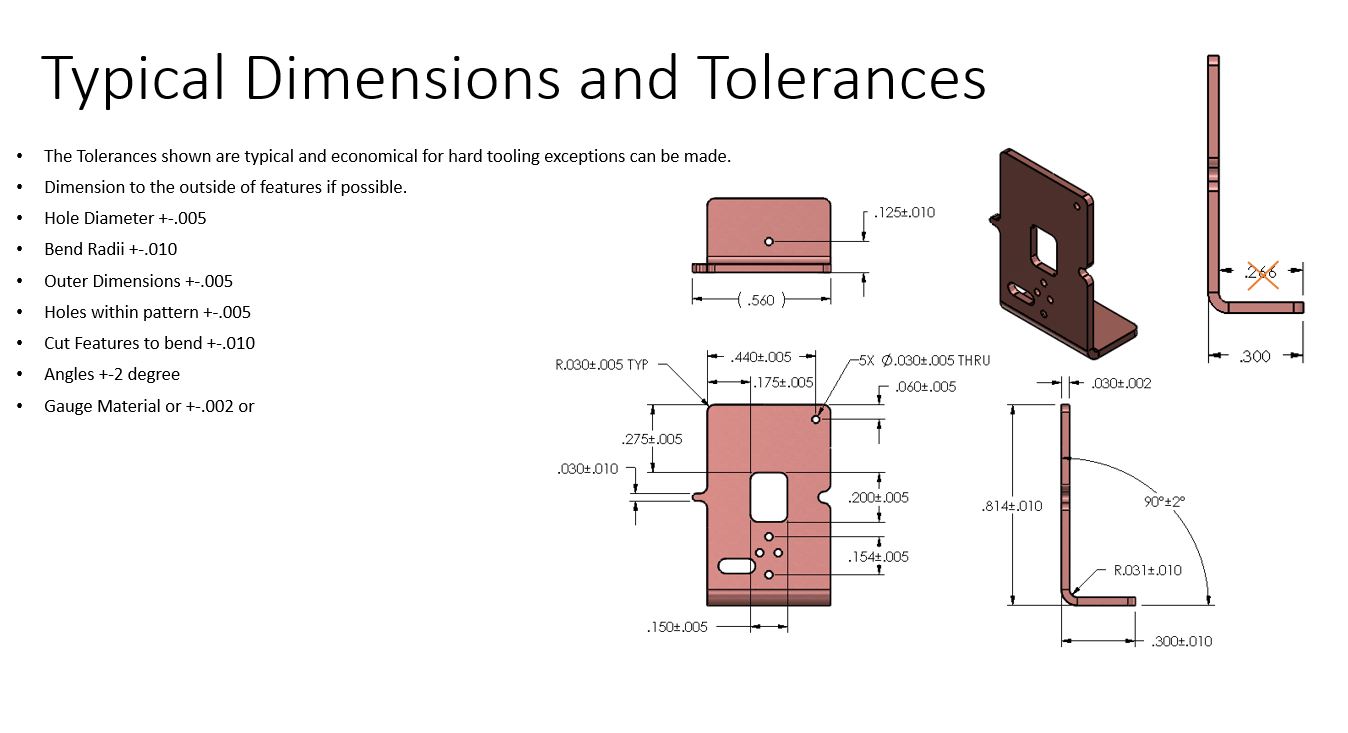

Below are dimensions and tolerances typical of stamped metal components.

Of course, exceptions apply. The tolerances shown are well suited to the progressive stamping process and thus ensure quality and cost-effective parts.

Progressive tooling is ideal for complex parts that require several steps to be completed from the flat strip to the finished part.

The drawing also indicates the ideal way to apply dimensions by using datums that can be controlled well and allow precise measuring.

Using a practical datum structure is convenient for the manufacturer, but it also makes your incoming quality control more efficient and reliable.

GD&T, when applied from well-established datums, can be helpful but avoid making it too complicated and requiring a CMM if possible.

We understand that most parts are not this simple, thus we work with our customers to co-engineer their parts.

This approach ensures you are getting quality parts due to the stamping specific design.

We are here to help make your parts work for you. Email us your stamping needs.