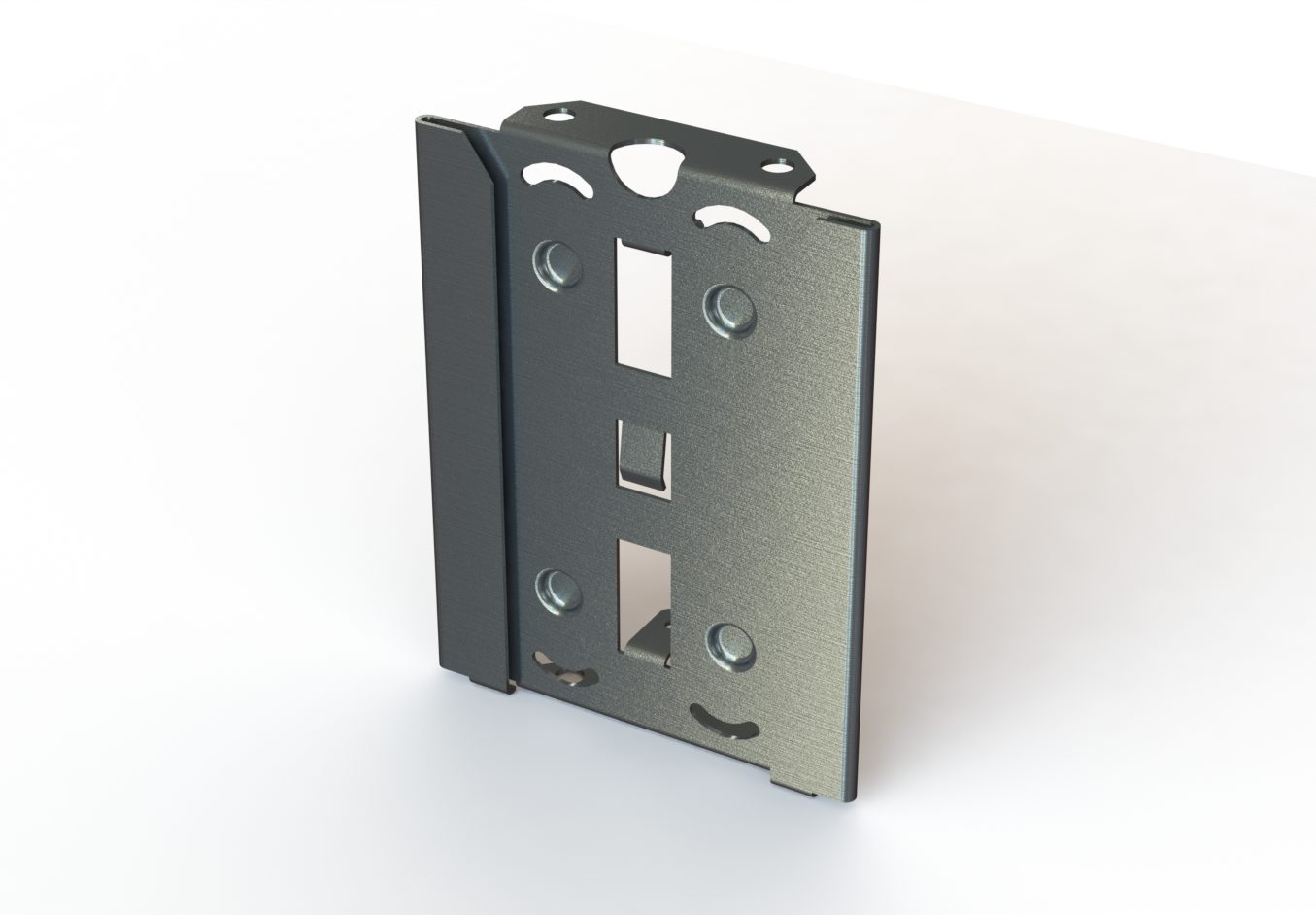

Sheet metal vs stamped metal part.

What is the difference between a sheet metal part and a stamped metal part?

The appearance can be similar depending on the features required.

Stamped metal parts are typically made from coil stock and processed in a stamping die that is set up in a punch press.

Suitable for larger quantity with improved precision.

The cost for stamping tooling is higher but offset by lower part cost.

Sheet metal Parts as the name implies are typically cut from flat sheet stock.

Parts are cut from the sheet using punching, laser, plasma or water jet cutting machines.

Post cutting each part and each bend is individually processed on a brake press.

Typically its a manual process, meaning the part is inserted and located by hand.

This approach is more suitable for lower quantities.

The tooling cost is lower but the part price is higher due to the slower process and manual handling.

Many parts start out as a sheet metal part but become a stamped part as quantities increase.

Quantities typical for sheet metal are in the hundreds.

Stamping quantities start once you get to a 1k or more.