Tooling cost what does it cover?

- Manufacturing Tools

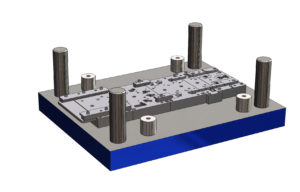

- Progressive tool

- Stage Tooling (tooling station to perform a single operation)

- Tool maintenance for the product lifetime. (included in our price as long as the tool remains at our facility)

- Secondary operations (only if specified)

- Tapping

- Custom part holding devices if needed (trays fixtures)

- In process inspection equipment (only if specified)

- Cameras

- Sensors

- Measuring Fixtures Gages (only if specified)

Tooling Cost Drivers

- Component complexity

- How Many Features

- Bends

- Draws & depth of draws

- Half shears

- Corner radii

- Bend radii

- Component feature size (the size of a feature in relation to the material thickness)

- Material thickness

- Drives clearances between punch and die

- Thinner material requires tighter clearance.

- Tolerance of the component features (smaller margins increase cost)

- Fragile components may need special handling tools.

- Component quantity

- ROI of tooling is better with high quantity of components

- Lower quantity runs may not justify a progressive tool, this is when we may introduce stage tooling

- Secondary operations

- Spot welding

- Hardware insertion

- Assembly

Need a quote or manufacturing feedback for your metal stampings?

Email Us here